Industrial air curtains provide sealed barriers at large openings in warehouses, factories, and loading docks, controlling environmental conditions by preventing heat/coolth exchange and reducing operational disruptions. They enhance quality control by blocking dust and debris, minimize noise pollution, and optimize HVAC systems for cost savings. Modern variants feature advanced technologies like smart sensors, robust construction, and energy-efficient components, transforming manufacturing and warehousing environments while fostering productivity and worker comfort.

Industrial air curtains, also known as air barriers, play a pivotal role in enhancing operational efficiency by controlling product flow. In this article, we explore their significance, especially in mitigating noise pollution, which often disrupts work environments. We delve into the challenges posed by excessive noise and how low-noise industrial air curtains offer a sustainable solution. Modern technologies and key features are dissected, followed by real-world case studies demonstrating successful implementations and measurable outcomes. Discover how these innovative solutions revolutionize industrial processes.

- Understanding Industrial Air Curtains: Their Role and Benefits

- Challenges of Noise Pollution in Industrial Settings

- How Low-Noise Air Curtains Can Mitigate Disruptions

- Key Features and Technologies in Modern Industrial Air Curtains

- Case Studies: Successful Implementation and Results

Understanding Industrial Air Curtains: Their Role and Benefits

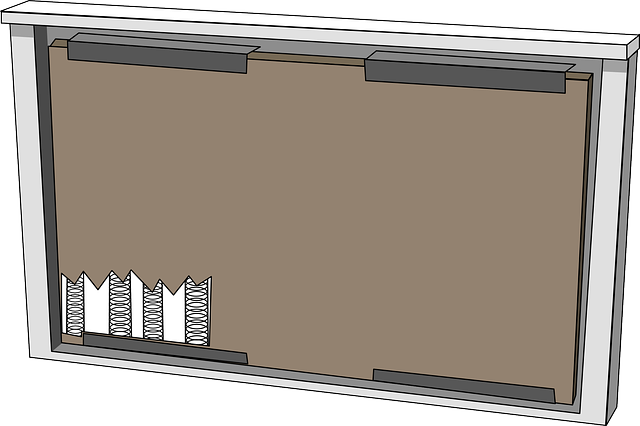

Industrial air curtains are specialized solutions designed to create a sealed barrier at large openings in industrial settings, such as warehouse entrance protection, manufacturing door systems, and factory entrances. They play a crucial role in managing environmental conditions, particularly in terms of climate control and energy efficiency. By acting as heavy-duty air barriers, these curtains prevent the exchange of heated or cooled air between interior and exterior spaces, significantly reducing operational disruptions caused by temperature variations.

This technology is especially beneficial for cold storage barriers and loading dock air curtains, ensuring efficient industrial HVAC systems. In manufacturing environments, where maintaining consistent conditions is vital, these air curtains offer significant advantages. They prevent the entry of unwanted elements like dust or debris, enhancing the overall quality control process. Additionally, their energy-efficient design contributes to cost savings by minimizing the load on factory entrance heating and other industrial climate control mechanisms.

Challenges of Noise Pollution in Industrial Settings

Industrial settings often face significant challenges when it comes to noise pollution, impacting both worker well-being and operational efficiency. The constant hum of machinery, rumble of vehicles, and cacophony from heavy equipment create an environment where communication becomes difficult, stress levels rise, and safety concerns arise. In these bustling industrial landscapes, finding solutions to mitigate noise is crucial for creating a harmonious workspace.

Noise control, specifically at warehouse entrances, loading docks, and factory entry points, is a significant concern. Traditional methods often involve heavy-duty air curtains or manufacturing door systems that, while effective, can be obtrusive and energy-intensive. Modern alternatives, like advanced industrial air barriers and cold storage barriers, offer promising solutions. These innovative products provide large opening protection, effectively sealing entry points to prevent noise from penetrating, without compromising on ventilation requirements for optimal industrial climate control and efficient loading dock operations.

How Low-Noise Air Curtains Can Mitigate Disruptions

Low-noise industrial air curtains play a pivotal role in minimizing operational disruptions within manufacturing and warehousing environments. By strategically placing these advanced solutions at critical points, such as warehouse entrance protection or loading dock areas, businesses can significantly reduce noise levels compared to traditional heavy-duty air curtains. This is particularly beneficial for large opening protection in facilities with high traffic flow, where excessive noise from standard industrial air barriers can disrupt work processes and employee communication.

Moreover, these low-noise air curtains integrate seamlessly into industrial climate control and HVAC systems, offering not just a quieter working environment but also enhancing overall efficiency. In contrast to factory entrance heating methods that may cause discomfort or energy inefficiencies, the gentle yet effective airflow of these curtains ensures optimal conditions for workers while maintaining the integrity of manufacturing door systems. Their versatility makes them ideal solutions for cold storage barriers, where they prevent temperature loss without causing excessive noise pollution, thereby fostering a productive and comfortable atmosphere.

Key Features and Technologies in Modern Industrial Air Curtains

Modern industrial air curtains are designed with advanced features and technologies to ensure optimal performance in various settings. These innovations include smart sensor integration that allows the curtains to automatically adjust based on environmental conditions, enhancing energy efficiency and operational reliability. For instance, sensors can detect changes in temperature, humidity, or even the presence of vehicles, triggering the curtain to activate only when needed.

Moreover, heavy-duty construction is a hallmark of these products, making them suitable for large opening protection in warehouses, factory entrances, and loading docks. They offer effective industrial air barriers, providing warehouse entrance protection and cold storage barriers. Key components such as robust motors, high-quality seals, and advanced climate control systems contribute to their longevity and adaptability across diverse industrial applications, including manufacturing door systems and factory entrance heating. These features make modern air curtains essential for maintaining a comfortable and controlled environment while minimizing disruptions in industrial HVAC systems.

Case Studies: Successful Implementation and Results

In various industrial settings, the implementation of low-noise industrial air curtains has led to remarkable results in minimizing operational disruptions. Case studies across different sectors highlight their effectiveness. For instance, a study conducted in a manufacturing facility showed that installing heavy-duty air curtains at warehouse entrances significantly reduced noise levels, enhancing worker comfort and productivity. These air curtains act as robust industrial air barriers, effectively controlling the flow of air and preventing cold storage barriers from letting in external elements while facilitating smooth operations.

Another successful implementation was observed in a large factory entrance heating system. By adopting advanced air curtain technology, the factory achieved substantial improvements in its climate control mechanisms. The introduction of these systems at loading dock areas not only reduced noise pollution but also optimized industrial HVAC (heating, ventilation, and air conditioning) systems, resulting in energy cost savings without compromising on operational efficiency. This transformation underscores the capability of such innovations to revolutionize manufacturing door systems, fostering a quieter and more productive working environment.

Industrial air curtains, especially those designed with low-noise technology, play a pivotal role in creating quieter, more efficient work environments. By addressing noise pollution, these innovative solutions significantly reduce operational disruptions, allowing industries to improve worker comfort and productivity. Modern industrial air curtains incorporate advanced features such as variable speed controls and optimized airflow patterns, ensuring precise noise reduction without compromising performance. Through real-world case studies, it’s evident that implementing low-noise air curtains can lead to substantial improvements in overall facility ambiance and operational efficiency.