Industrial air curtains are specialized ventilation solutions that create robust barriers against external elements while maintaining optimal internal climate control in warehouses, manufacturing facilities, and cold storage settings. Integrating seamlessly with HVAC systems, these curtains enhance energy efficiency, protect against harsh weather conditions, and streamline material handling processes. Understanding specific industry needs and factors like door size, speed, environmental conditions, and energy efficiency is crucial for selecting the right industrial air curtain to optimize performance and reduce operational costs.

“Industrial air curtains are indispensable in maintaining temperature separation and energy efficiency within facilities. This article explores the multifaceted role of these innovative solutions, highlighting their benefits for various industries. We delve into the science behind insulated air curtains, explaining how they create a robust barrier to regulate temperature and prevent energy loss. From warehousing to manufacturing, discover optimal applications and learn how to choose the perfect insulated air curtain to meet your specific industrial needs.”

- Understanding Industrial Air Curtains: Their Role and Benefits

- The Science Behind Insulated Air Curtains and Temperature Separation

- Applications: Where Insulated Air Curtains Excel

- Choosing the Right Insulated Air Curtain for Your Industrial Needs

Understanding Industrial Air Curtains: Their Role and Benefits

Industrial air curtains are specialized ventilation solutions designed to create a powerful barrier against external elements while maintaining optimal internal climate control. These innovative systems play a pivotal role in various industrial applications, offering numerous benefits that enhance efficiency and productivity. By acting as a robust industrial air barrier, they prevent unwanted air exchange, ensuring that the internal environment remains consistent and isolated.

In settings like warehouses, manufacturing facilities, and cold storage areas, where temperature regulation is critical, industrial air curtains are invaluable. They provide effective warehouse entrance protection and loading dock air curtains, guarding against harsh weather conditions while facilitating efficient material handling processes. Moreover, these heavy-duty air curtains integrate seamlessly with factory entrance heating and industrial HVAC systems, contributing to energy efficiency and overall operational excellence in demanding manufacturing environments.

The Science Behind Insulated Air Curtains and Temperature Separation

Insulated air curtains use a sophisticated combination of airflow and temperature regulation to achieve effective separation in industrial settings. They function by creating a powerful barrier of controlled air at entry points, like warehouse entrances or factory doors. This barrier prevents external conditions from infiltrating the interior space.

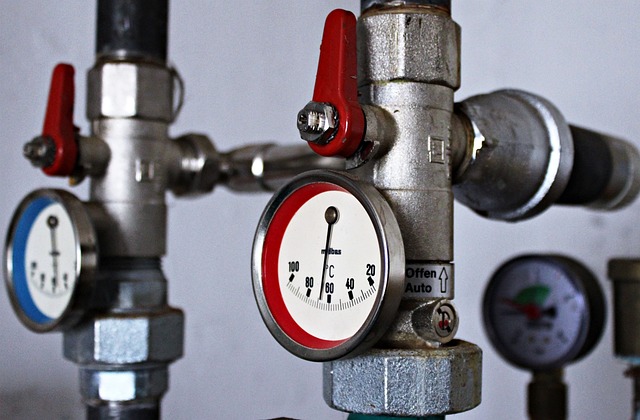

These air curtains are designed with heavy-duty materials and advanced manufacturing door systems that can withstand harsh environments. They work in tandem with industrial HVAC systems to maintain desired temperatures, effectively protecting against extreme weather conditions and ensuring optimal climate control for sensitive operations. Whether it’s a cold storage facility or a loading dock, these curtains provide robust protection, enhancing energy efficiency and reducing operational costs associated with heating or cooling large openings.

Applications: Where Insulated Air Curtains Excel

Insulated industrial air curtains excel in a variety of applications where maintaining temperature separation is paramount. In industries like manufacturing and warehousing, these air curtains serve as effective heavy-duty solutions for large opening protection. They ensure that cold storage barriers remain intact, preventing external elements from disrupting the delicate climate control needed for sensitive goods.

For instance, at factory entrances or loading docks, industrial air curtains provide a robust barrier against harsh weather conditions, thereby enhancing the efficiency of industrial HVAC systems. Their versatility is evident in maintaining the integrity of manufacturing door systems, making them indispensable for businesses seeking to optimize their operations and reduce energy costs associated with climate control.

Choosing the Right Insulated Air Curtain for Your Industrial Needs

When selecting an insulated air curtain for industrial applications, understanding your specific needs is key. Different industries have varied requirements when it comes to temperature separation and airflow control. For instance, a cold storage facility will need a heavy-duty air curtain to prevent warm air from entering, maintaining cold storage barriers and ensuring the integrity of the product’s temperature. Conversely, a manufacturing plant might require an industrial HVAC system that accommodates large openings and provides efficient warehouse entrance protection.

Choosing the right industrial air barrier means considering factors like door size and speed, environmental conditions, and desired energy efficiency. For instance, loading dock air curtains should be robust enough to withstand frequent use while offering effective factory entrance heating or cooling. The right fit ensures optimal performance, minimizes energy loss, and contributes to a more sustainable and cost-effective industrial climate control system.

Industrial air curtains are not just a novelty; they are a game-changer in maintaining temperature separation and enhancing operational efficiency. By understanding their role, the science behind them, and their diverse applications, businesses can make informed choices to suit their specific needs. When selecting an industrial air curtain, consider factors like space requirements, desired temperature control, and environmental conditions to ensure optimal performance and energy savings. With the right fit, these curtains can revolutionize how industries manage internal climates, contributing to a more sustainable and productive future.