Industrial air curtains are specialized ventilation solutions that maintain temperature separation in various settings, optimizing manufacturing, storage, and logistics by preventing external elements from entering sensitive areas. These heavy-duty barriers, powered by advanced door systems, offer precise climate control for warehouses, cold storage, and loading docks, enhancing energy efficiency and reducing costs. Key applications include large opening protection, factory entrance heating, and industrial climate control, with tailored systems based on environmental conditions and specific industry needs. Case studies highlight their effectiveness in improving operational efficiency and lowering expenses across diverse industries.

“Industrial air curtains are revolutionary tools that maintain temperature separation, enhancing energy efficiency and process control in various sectors. This article delves into the multifaceted world of these innovative solutions, exploring their role, benefits, and underlying science. From understanding how they work to examining real-world applications across industries, we’ll guide you through the key considerations when choosing the right insulated air curtain. Additionally, case studies will highlight successful implementations, showcasing the impact of these game-changing technologies.”

- Understanding Industrial Air Curtains: Their Role and Benefits

- The Science Behind Insulated Air Curtains: How They Work

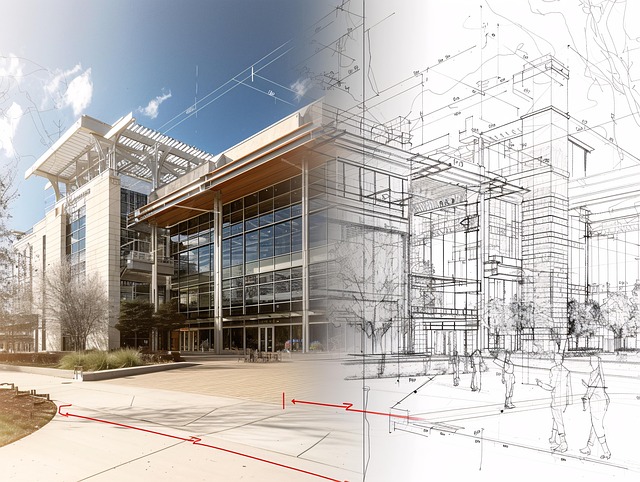

- Applications of Insulated Air Curtains in Various Industries

- Factors to Consider When Choosing Insulated Air Curtains

- Case Studies: Successful Implementation of Insulated Industrial Air Curtains

Understanding Industrial Air Curtains: Their Role and Benefits

Industrial air curtains are specialized ventilation solutions designed to maintain temperature separation in various industrial settings. They play a pivotal role in regulating indoor climates, ensuring optimal conditions for manufacturing processes, storage, and logistics. By acting as robust industrial air barriers, these curtains prevent external elements from entering sensitive areas, thereby enhancing energy efficiency and reducing operational costs.

In warehouses, heavy-duty air curtains at entrance points serve as effective solutions for large opening protection. They control the flow of air, preventing cold storage barriers from being breached, which is crucial in maintaining consistent temperature levels within manufacturing facilities and cold storage spaces. This technology complements industrial HVAC systems by offering precise, localized climate control, making them indispensable for efficient and sustainable operations in demanding environments.

The Science Behind Insulated Air Curtains: How They Work

Insulated air curtains are innovative solutions designed to maintain temperature separation in industrial settings. They work by generating a powerful flow of heated or cooled air, creating a barrier that prevents external elements from entering sensitive areas. This process is achieved through advanced manufacturing door systems that incorporate heavy-duty components and precise engineering.

These industrial air barriers are particularly effective for warehouse entrance protection, cold storage barriers, and loading dock air curtains. By acting as efficient industrial climate control mechanisms, they ensure the integrity of HVAC systems in factories and manufacturing facilities. This technology is crucial for maintaining optimal conditions in environments where large openings need protection from external weather conditions or unwanted intrusions, enhancing overall efficiency in these industries.

Applications of Insulated Air Curtains in Various Industries

Insulated air curtains have a wide range of applications across various industries where maintaining temperature separation is crucial. In manufacturing and warehousing, they serve as effective industrial air barriers, safeguarding against the loss of heated or cooled air at warehouse entrance protection points, thereby enhancing energy efficiency. These heavy-duty air curtains are particularly useful in loading dock air curtains settings, ensuring that cold storage areas remain insulated from external environments.

Furthermore, their utility extends to factory entrance heating and industrial climate control systems, where they help regulate internal temperatures and prevent the infiltration of outside elements. Large opening protection is another area where these industrial HVAC systems excel, making them indispensable for creating a robust barrier in doors and entry points that require constant temperature regulation.

Factors to Consider When Choosing Insulated Air Curtains

When selecting insulated air curtains for industrial applications, several key factors come into play to ensure optimal performance and energy efficiency. Firstly, consider the specific environmental conditions in which the air curtain will operate. This includes temperature extremes, humidity levels, and the presence of hazardous materials or debris that might affect the curtain’s functionality. For instance, heavy-duty air curtains designed for cold storage barriers require robust insulation and heating systems to maintain the desired internal temperature.

Additionally, the size and configuration of the opening being covered are critical. Large openings, such as those in warehouse entrance protection or loading dock air curtains, necessitate powerful industrial HVAC systems capable of handling significant airflow while maintaining temperature separation. The type of industry and its unique requirements should also guide your choice. Different manufacturing door systems and factory entrance heating needs may demand specialized features like customizable control panels, automatic sensors, or advanced insulation materials to prevent heat loss in cold environments and maintain a comfortable workplace in hot climates.

Case Studies: Successful Implementation of Insulated Industrial Air Curtains

In various industries, the successful integration of insulated industrial air curtains has been a game-changer in maintaining temperature separation and enhancing operational efficiency. Case studies across diverse sectors highlight their effectiveness in controlling environmental conditions within warehouses, factories, and cold storage facilities. For instance, one leading e-commerce logistics company implemented heavy-duty air curtains at large warehouse entrance points to prevent the loss of conditioned air during loading and unloading processes. This not only improved energy efficiency but also reduced the need for additional factory entrance heating systems, significantly lowering operational costs.

Another successful story involves a manufacturing plant that relied on advanced industrial HVAC systems to maintain a consistent environment across its production floors. By installing high-performance air curtains at critical doors and loading docks, they were able to contain temperature fluctuations and prevent cold storage barriers from compromising the overall climate control. This strategic use of industrial air barriers resulted in enhanced product quality and increased productivity, demonstrating the versatility and impact of these innovative solutions in diverse manufacturing door systems.

Industrial air curtains, with their ability to maintain temperature separation, are a game-changer in various industries. By understanding their role, the science behind their operation, and the diverse applications they offer, businesses can make informed decisions. When choosing these curtains, considerations such as environmental conditions, space requirements, and specific industry needs are crucial. Successful case studies highlight their effectiveness, proving that insulated industrial air curtains are a reliable solution for enhancing energy efficiency and process control in today’s demanding business landscape.